- The Varato Letter

- Posts

- Why Smart Manufacturers Are Quietly Switching to PIM Systems

Why Smart Manufacturers Are Quietly Switching to PIM Systems

Welcome to The Varato Letter, Sponsored by Harris Web Works.

Every Saturday, we share insights with 1,100+ supply chain leaders on modernizing business operations for the digital age. This newsletter will be Free for the reader forever. Enjoy!

To learn more about how Harris Web Works can help you to future proof your manufacturing wholesale or distribution business, click here.

6 reasons why your manufacturing business NEEDS a PIM system in 2024 (...this will transform your business):

Most manufacturers are still sending product data sheets manually to distributors...

Using spreadsheets, PDFs, and emails.

But there's a better way.

Here's why Product Information Management (PIM) systems are becoming ESSENTIAL for manufacturers:

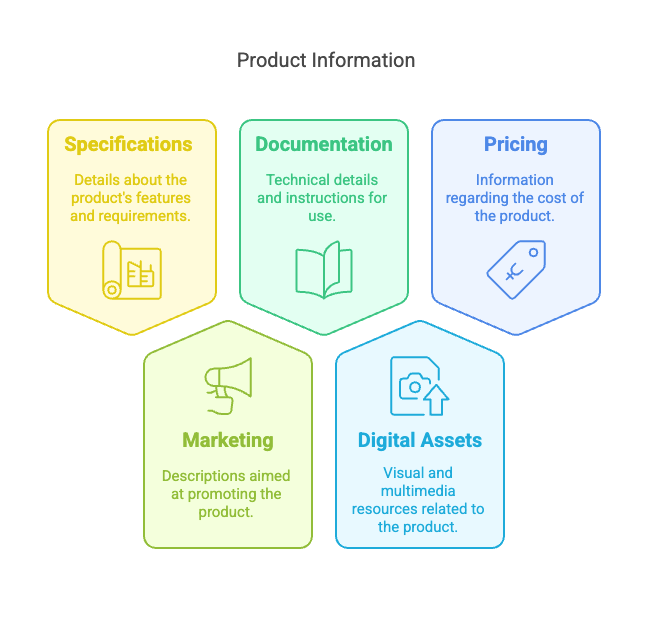

1️⃣ Single Source of Truth — Centralize all product data in one hub

Think of a PIM as your digital command center. Instead of juggling multiple spreadsheets across departments, everything lives in one place:

Product specifications

Marketing descriptions

Technical documentation

Digital assets (photos, videos, manuals)

Pricing information

Real-world example: One of our manufacturing clients previously managed 50,000+ SKUs across 23 different spreadsheets. After implementing a PIM system, they now update everything in one place, eliminating version control issues and reducing errors by 94%.

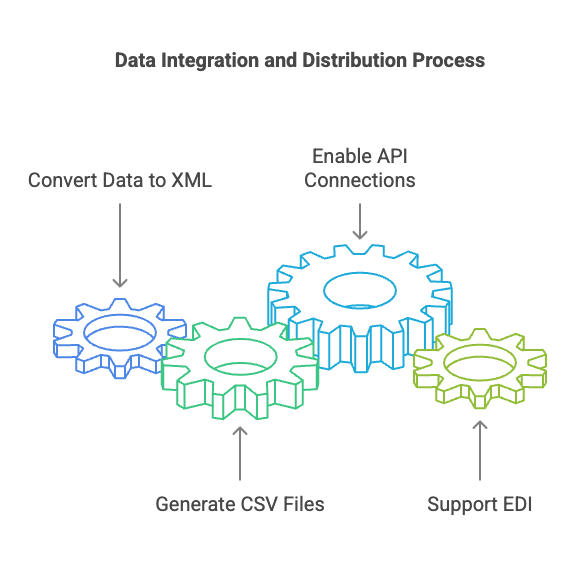

Modern PIM systems can automatically format and send your product data to different channels:

Convert data to XML for major distributors

Generate CSV files for marketplace uploads

Enable API connections for real-time updates

Support EDI for traditional systems

We recently helped a plumbing manufacturer automate their data distribution to 12 major distributors, cutting their product update time from 2 weeks to just 4 hours.

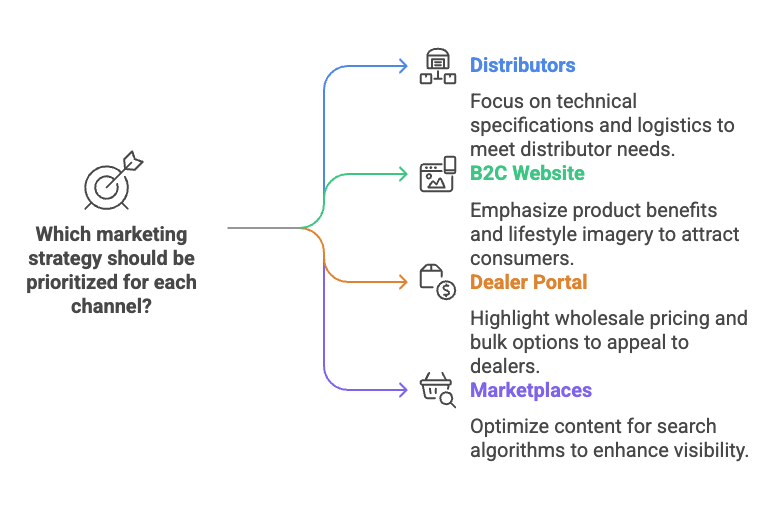

3️⃣ Channel-Specific Customization — Tailor product information for different channels

Different channels need different information:

Distributors: Focus on technical specs, shipping weights, packaging dimensions

B2C website: Emphasize benefits, features, lifestyle images

Dealer portal: Highlight wholesale pricing, bulk ordering options

Marketplaces: Optimize for search algorithms

Example: A industrial parts manufacturer uses their PIM to automatically generate:

Technical data sheets for distributors

SEO-optimized descriptions for their website

Simplified spec sheets for sales teams

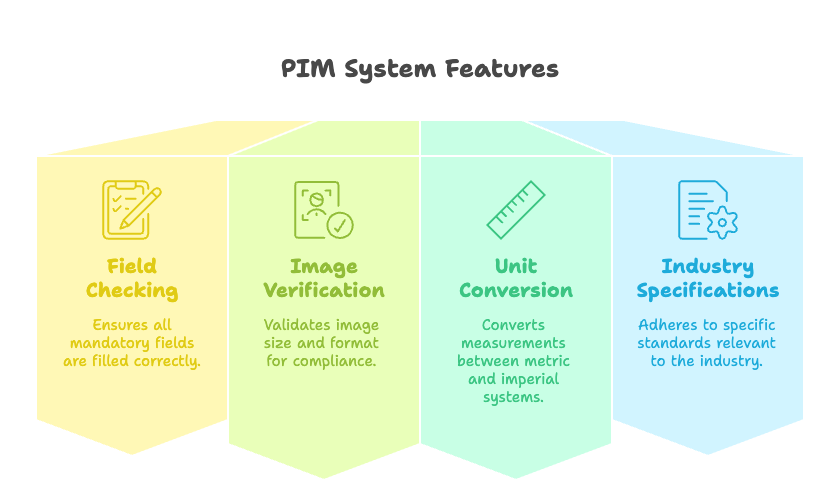

4️⃣ Data Validation & Compliance — Ensure all product listings meet requirements

Modern PIMs include built-in validation tools:

Mandatory field checking

Image size and format verification

Unit conversion (metric/imperial)

Industry-specific compliance rules

Case study: An automotive parts manufacturer reduced listing rejections by 87% after implementing automated validation checks through their PIM.

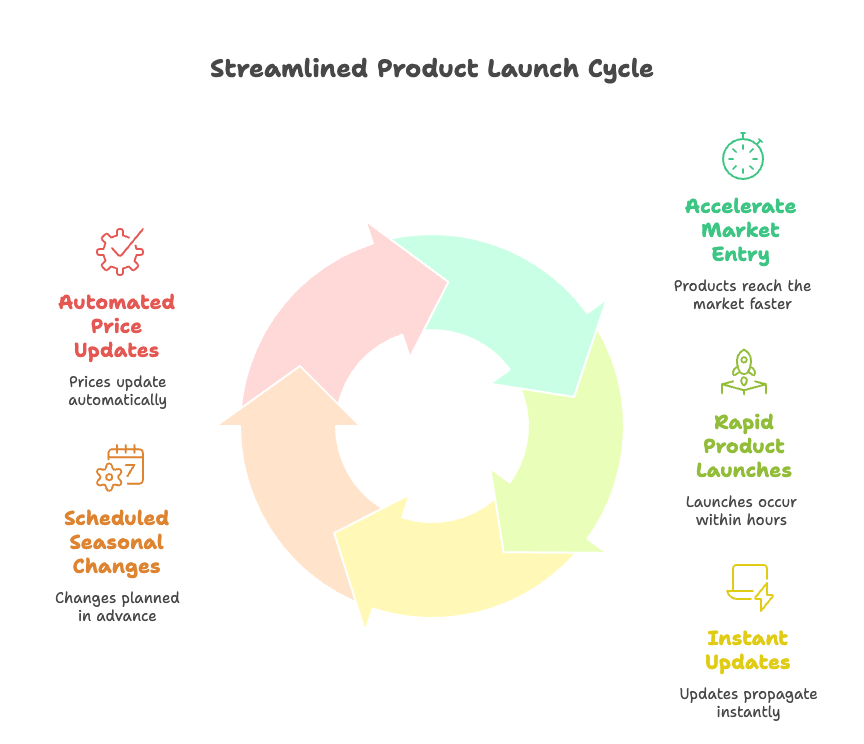

5️⃣ Faster Time to Market — Launch products quickly across all channels

With a PIM system:

New product launches take hours instead of weeks

Updates propagate instantly across all channels

Seasonal changes can be scheduled in advance

Price updates deploy automatically

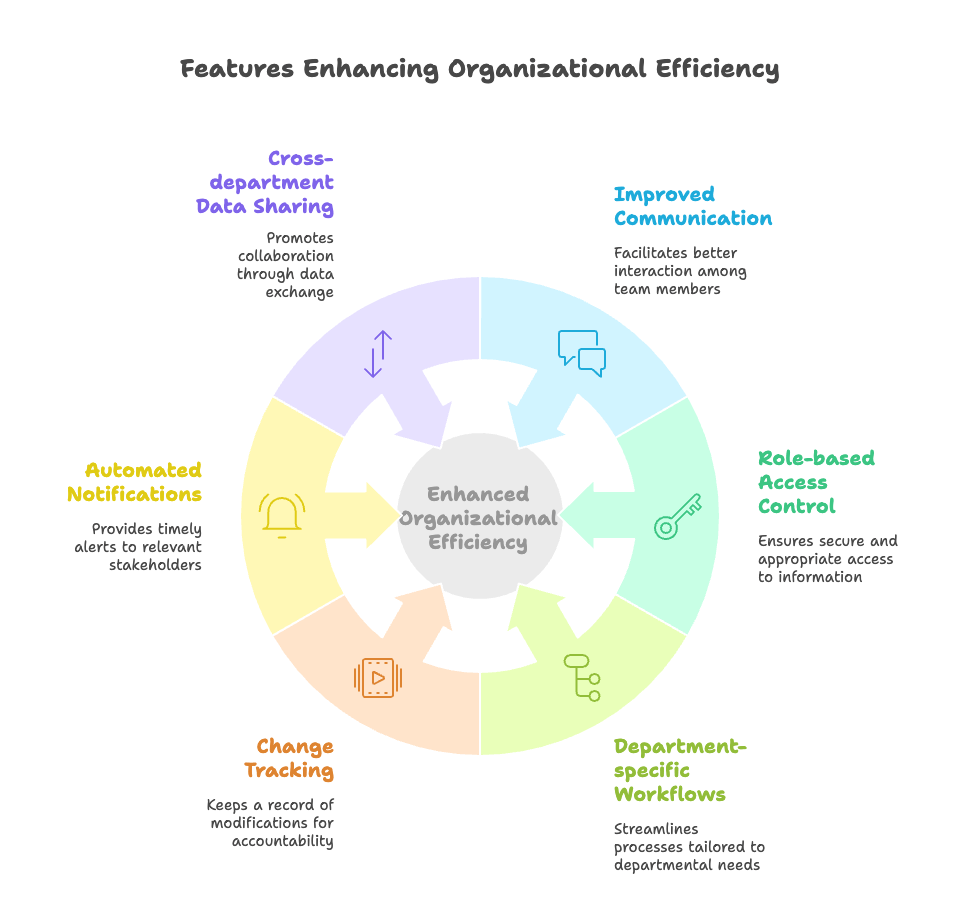

6️⃣ Improved Collaboration — Streamline data sharing between departments

Modern PIMs enable:

Role-based access control

Department-specific workflows

Change tracking and version history

Automated notifications

Cross-department data sharing

The manufacturing industry is changing fast.

In the next few years, organized product data will be mandatory.

Not optional.

Get ahead of the curve now.

Whenever you're ready, here's how we can help you:

Harris Web Works is a digital transformation agency that helps supply chain partners (manufacturers, wholesalers & distributors) meet new generational buyer demands & expectations by installing streamlined e-commerce systems.

To learn more about how we can help you future-proof your business, click here.